Production programm - Piston Rings

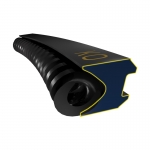

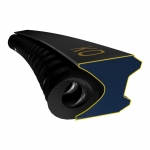

Piston rings

For over 80 years, we specialize in producing piston and sealing rings. With experience based on meeting the requirements of our customers is our portfolio of piston ring very wide especially in the field of design, materials and surface treatments.

Piston Rings Komarov pursues a long-term goal to deliver quality products that perfectly meet customer requirements while ensuring an optimum balance between the use value and price. This can not be achieved without close cooperation with our customers to develop new products optimized for various use and application.

Use:

- Petrol four-stroke engines

- Diesel four-stroke engines

- Piston compressors

- Two-stroke engines

Market

- Automotive manufactures

- Engine manufactures

- Agricultural industry

- Garden engineering (chainsaw, mowing machines, …)

- Piston compressors (air conditioning, refrigeration, …)

- Tractors

- Motorcycles, scooters

- Small marine engines

PRODUCTION TECHNOLOGy

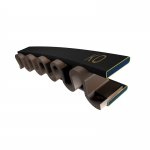

We produce the piston and sealing rings in range of diameters 25mm - 140mm. Cast iron rings produced using the double turning machine technology and steel rings by coiling steel blank and by thermo-forming called thermofixing.

Material

Grey cast iron - Alloyed cast iron - Ductile cast iron - Steel

Cast iron castings of different material modifications in accordance with valid Czech and foreign Standards and according to the Customers' requests.

The initial materials in the area of piston rings are in accordance with the CS Standard ISO 6621-3, classes 10,20 and 50,60.

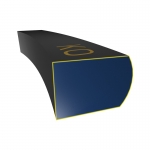

SURFACE TREATMENt

Phosphate, Cr, porous Cr, Chrome-composite BCr, Chrome-diamond BDG, MO spraying, Nitridation, PVD (CrN, CrAlN, DLC)

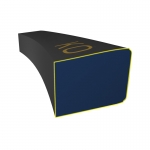

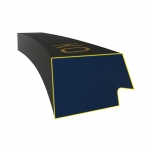

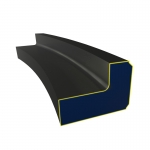

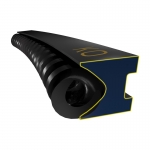

Types of Piston Rings (ISO 6621-1; ISO 6622-6626) | ||

|---|---|---|

Cross section | ||

Rectangular ring | R | |

Taper faced ring | M | |

Keystone ring | K, T | |

Half keystone ring | HK, HT | |

Taper faced Napier ring | N | |

L ring | L | |

Slotted oil control ring | S | |

Beveled-edge oil control ring | D | |

Double-bevelled oil control ring | G | |

Slotted oil control ring with coil expander | SSF | |

Slotted oil control ring (double - bevelled) with coil expander | DSF | |

Double-bevelled oil control ring with coil expander | DSF-C | |

Top-bevelled profile grinded iol control ring with coil expander | GSF | |

Multi-piece steel-rail oil control ring type MINIFLEX | MINIFLEX | |

Working surface | ||

Straight faced | R | |

Taper faced | M | |

Barrel-faced symmetrical | B | |

Barrel-faced asymmetrical | BA | |

Edge features | ||

Inside bevel top side | IF | |

Inside step top side | IW | |

Inside bevel bottom side | IFU | |

Inside step bottom side | IWU | |

Inside edges chamfered | KI | |

Peripheral edges chamfered | KA | |

Joint shapes | ||

Standard joint | S | |

Joint with side notch | NE | |

Joint with internal notch | NH | |

Hook joint | SH | |

Overlapped joint | SU | |

Oil slot | ||

Slotted oil control ring | – | |

Drilled oil control ring | – | |